International standards

The HVAC market is forecasted to grow at a projected compound annual growth rate (CAGR) of 3.9%, with a prediction to reach $370 billion by 2030. But in reality, the HVAC and plumbing industry is changing rapidly, with operators facing new challenges like never before. Whether it’s rising costs, the uncertain economy, increasing competition, or the workforce shortage, there’s no doubt the HVAC and plumbing market is evolving. So how do you adapt? That’s the key question. My t...

EDEN, a pioneering startup in the heating, ventilation and air conditioning (HVAC) industry, has officially announced the launch of its Instant Quote solution that improves the transparency and accuracy of purchasing residential HVAC equipment. EDEN’s Instant Quote application integrates into an HVAC contractor’s website to provide a 24/7 interactive online experience for homeowners by providing them with accurate estimates based on the contractor’s pricing. EDEN’...

The demands of HVAC professionals are unique, often requiring them to work in extreme conditions that necessitate gear that can keep up. Every day, these workers face fluctuating temperatures and a variety of hazardous environments. As such, the development of their uniforms has become a critical focus in the industry, with the goal of transforming them from basic work wear into high-performance apparel that meets the unique challenges of the HVAC work environment. Modern HVAC technicians&rsquo...

ESS Expo, the UK’s largest environmental event, has released its full agenda for its 2024 show, which is set to welcome a record number of over 12,000 visitors and over 600 exhibiting companies. Returning to the NEC (National Exhibition Center), Birmingham, from 11-12 September 2024, the show unites five key industry events – Resource & Waste Management Expo (RWM), Energy, Fuels & Decarbonization Expo (EFD), Water Resource Management Expo (WRM), Cont...

Bradford White Corporation, an industry-renowned manufacturer of water heaters, boilers, and storage tanks, announced the acquisition of FloLogic, a North Carolina-based manufacturer of premium plumbing leak detection and automatic shut-off solutions for homes and light commercial buildings. The acquisition aligns with Bradford White’s commitment to innovation and quality and enhances the company’s smart technology offerings. premium IoT-based leak detection FloLogic’s prem...

Vetter GmbH, a pioneer in safety solutions, is proud to unveil its latest innovative product: MAGNASEAL. This groundbreaking magnetic urethane sheet redefines how first responders and industry professionals handle hazardous material leaks. The Vetter MAGNASEAL Magnetic Sealing Patch instantly stops hazardous leaks. The patches are a highly safe and effective way to control liquids and gaseous substances leaking out of magnetic objects. Thanks to its unique self-adhesive, patented sealing soluti...

News

RUSAL, one of the world's largest aluminum producers, has verified the carbon footprint of its products, reaffirming its status of a pioneering global low-carbon aluminum producer. The independent verification of greenhouse gas emissions was conducted by TÜV AUSTRIA Standards & Compliance, one of the world's foremost providers of certification, testing, inspection, and verification services. The analysis confirmed that 100% of RUSAL’s metal meets the low carbon aluminum (LCA) benchmark of less than 4 t CO2/t within Scopes 1&2, aligning with benchmarks from pioneering international analytical agencies such as Fastmarkets and S&P Global. Additionally, in 2023, RUSAL improved the full scope carbon footprint of its LCA brand ALLOW to 5.9 tons of CO2 equivalent per ton of metal, down from 6.1 tons the previous year. Use of renewable energy sources In 2023 alone, RUSAL retrofitted 309 electrolyzers across its smelters This remarkable achievement is primarily due to the use of renewable energy sources, especially hydropower, powering RUSAL’s production facilities, and an extensive modernization program for aluminum smelters. The program includes the renewal of electrolyzers, transition to pre-baked anode technology, installation of new gas emissions treatment facilities, and improvements in air monitoring systems. In 2023 alone, RUSAL retrofitted 309 electrolyzers across its smelters. The modernization of alumina assets, which significantly contribute to the carbon footprint of the final product, is also a key focus. RUSAL’s ALLOW INERTA™ brand, featuring the lowest carbon footprint in the industry, is one of the frontrunners of RUSAL’s decarbonization efforts. Its cutting-edge production technology significantly reduces the total volume of greenhouse gas emissions during the electrolysis process. This solution allows for reducing carbon dioxide emissions within Scope 1 and 2 to 0.01 tons of CO2 equivalent per ton of aluminum (compared to the industry average of 11.4 tons of CO2 equivalent). RUSAL’s decarbonization strategy Increasing the recycled content in primary products is another critical component of RUSAL’s decarbonization strategy. A major milestone in this area is the production of primary equivalent foundry alloys (PEFA) with a 30% share of secondary aluminum content, which has successfully launched and been delivered to its first customers. As a low-carbon aluminum producer, RUSAL is at the forefront of developing a green economy. Its decarbonization strategy is fully in line with the aspirations of the largest international aluminum-consuming companies to reduce their carbon footprint and achieve carbon neutrality.

Geoclima is excited to announce a significant milestone in its journey — Geoclima Group has been acquired by Munters Group, a distinguished Swedish firm founded in 1955 and listed on the large cap of Nasdaq Stockholm. This strategic acquisition represents a major step forward, unlocking immense growth opportunities for Geoclima in the dynamic data center market. Munters’ Data Center Technologies (DCT) Munters’ Business Area Data Center Technologies (DCT) specializes in creating advanced climate solutions for data centers worldwide. DCT has strategically added Geoclima’s high-efficiency chillers to its portfolio Renowned for innovative technologies such as evaporative cooling (e.g., Oasis) and pumped refrigerant systems (SyCool), as well as successful sales of computer room air handlers, DCT has strategically added Geoclima’s high-efficiency chillers to its portfolio. This addition fills a crucial gap, making it a perfect strategic fit for both companies. Munters acquires Geoclima This acquisition will significantly expand Geoclima’s presence in the broader data center market, offering growth opportunities far beyond its current footprint. With ongoing digitalization and the rise of AI, the data center segment is increasingly attractive for any chiller manufacturer. Scaling up to fully capture these opportunities in a competitive market requires smart, value-adding partnerships, which Geoclima has found through this acquisition. Focus on energy-efficient solutions Stefan Aspman, President of Munters DCT and Group Vice President of Munters Group, shared his excitement, stating: “The integration of Geoclima’s technology and talent with Munters is truly exciting. Both companies share a similar DNA, focusing on energy-efficient solutions tailored to meet customer needs.” Stefan Aspman adds, “Customer focus and innovation are at the core of both organizations, and with our combined team of talented and devoted individuals in heat transfer, refrigeration, engineering, and operations, the sky is the limit for what we can achieve together.” Partnership to enable new avenues for growth Joining forces will open new avenues for growth and success, providing a stronger foundation Geoclima understands that change can bring uncertainty, but this acquisition is about opening new doors of opportunity rather than introducing risk or dramatic change. The decision to sell the company at this point was made with careful consideration of timing, trust, and business rationale. Joining forces will open new avenues for growth and success, providing a stronger foundation for the future and creating exciting opportunities for everyone involved. Munters and Geoclima collaboration The official completion of the acquisition has been signed today, although certain customary closing activities still need to be finalized. During this period, Munters will continue to work closely with Geoclima to determine a firm closing date, likely by the end of September.

A. O. Smith, a pioneer in water heating and water treatment, announces the addition of the Voltex® MAX hybrid electric heat pump water heater (HPWH) to its growing family of sustainable products. The Voltex MAX HPWH uses a new smart valve to deliver maximum hot water while the heat pump technology provides maximum savings at all times. The Voltex MAX HPWH can deliver homeowners around 40% higher First Hour Ratings than similarly sized electric water heaters and heat pump water heaters. Using newly available advanced operating modes, the Voltex MAX provides more hot water than previous iterations of heat pump water heaters. Voltex MAX heat pump water heater “The introduction of the Voltex MAX heat pump water heater is the culmination of many years of innovation designed to support the industry-wide shift toward decarbonization. Through dedicated research, A. O. Smith was able to develop a unit that not only supports electrification goals, but also supports homeowners and contractors,” said Arthur Smith, A. O. Smith product manager. “The Voltex MAX unit incorporates features that our customers know and love, such as integrated leak detection, while also introducing new enhancements like our unique smart valve technology.” Voltex MAX unit’s smart valve technology Voltex MAX unit’s smart valve technology allows a contractor to install a smaller tank in an area The Voltex MAX unit’s smart valve technology allows a contractor to install a smaller tank in an area where space is tight and still get comparable performance to a larger tank by using the unit’s Hot Water + modes. It also allows homeowners to customize the unit’s performance to exactly the way they live and use hot water. All Voltex MAX models come with three levels of Hot Water + modes that each provide about 10-12% extra hot water. Hot Water + is a permanent operating mode and the unit will continue to function at the selected level until instructed otherwise. For temporary periods of increased demand, the Voltex MAX HPWH also offers a Guest Mode. This mode allows the unit to provide maximum hot water output for up to seven-day increments. A. O. Smith’s iCOMM™ connectivity platform An automatic shutoff valve also comes standard on all Voltex MAX models to further protect homes Customers can also benefit from using A. O. Smith’s iCOMM™ connectivity platform, which is fully integrated on all Voltex MAX units. This technology supports features like anti-leak technology through the use of integrated leak detection and a smart anode. For added peace of mind, the smart sensor provides notifications through A. O. Smith’s notification-enabled mobile app in the event of a detected leak. An automatic shutoff valve also comes standard on all Voltex MAX models to further protect homes. Heat pump water heater The smart anode adapts to local water conditions, protecting and extending the life of the water heater, and it displays an error code on the control panel when it needs to be replaced. Demand response and time-of-use capabilities make it even easier to save money by integrating a heat pump water heater into the growing number of utility smart grid programs. Using the A. O. Smith mobile app, professionals and homeowners can remotely monitor and adjust the water heater to improve performance and increase savings.

Vaisala, a pioneer in measurement technology, partners with the BMW Group to implement real-time Xweather air quality data in the new BMW X1, X2, and 2 series, as well as MINI and MINI Countryman, through the new iDrive9 infotainment system. The addition is part of the BMW Group’s rollout of Android-based OS9, which has started in the UK and will be rolled out globally as of now. Xweather air quality monitoring informs drivers about current and expected conditions during their journey. Critical information, such as the air quality category will be accessible to drivers through the infotainment system, to help them make driving decisions that can impact their health and safety. As air quality categorization can vary between countries, the data presentation will be adapted to each user's region. Health-based guideline level “This partnership with the BMW Group opens completely new opportunities for drivers to make healthy choices on the road. It also shows that innovative automotive players like the BMW Group are working to make every car journey safer. With our air quality data on board, BMW drivers can choose clean routes and adjust indoor air circulation to stay safe and healthy,” says Petri Marjava, Head of Automotive at Vaisala Xweather. Air pollution affects everyone’s health, but certain groups may be harmed more Air pollution has severe health impacts worldwide, with the European Union reporting that 96% of EU urban populations are exposed to fine particulate matter above the health-based guideline level set by the World Health Organization. Air pollution affects everyone’s health, but certain groups may be harmed more, especially those with pre-existing respiratory and cardiac problems. Almost nine out of 10 people living in urban areas worldwide are affected by air pollution. Emissions from exhaust systems “We know that airborne pollutants affect people all over the world, but it is not as easy to deal with as other risk factors like traffic or the physical environment because you cannot always see or smell it. Especially for people in urban and industrialized areas, local pollution can cause serious harm over time. Your daily commute shouldn’t be a health risk, and with air quality data on board, we give drivers back control over the air they breathe,” continues Petri Marjava. In addition to drivers’ health, air pollution can significantly impact vehicle performance, by clogging cabin filters as well as reducing engine performance, power output, and tire traction. Local pollution can also negatively affect vehicle emissions from exhaust systems. With air quality data accessible through the infotainment system, drivers can make choices that improve their vehicle performance and reduce maintenance needs. implementation of air quality data The partnership starts with all the new BMW X1, X2, and 2 Series Active Tourer models, and MINI and MINI Countryman. In the future, the BMW Group is looking to expand the implementation of air quality data to other models in its fleet, as it continues to roll out the new OS9 infotainment system. Vaisala Xweather air quality forecast combines advanced physical modeling techniques and long-range dispersion models with machine learning, and weather and environmental data to provide the best possible accuracy. The BMW Group has used Vaisala Xweather’s weather data for years, and the company’s high-quality delivery, support, and constant monitoring capabilities meant adding air quality data was a meaningful choice.

Alleima, is thrilled to announce its latest compressor valve steel Freeflex® Versa, a successor of the award-winning Freeflex® Core. The new material contributes to designing smaller, more sustainable, and more energy-efficient compressors for refrigerators, and freezers. It is a pioneering compressor valve steel with exceptional fatigue resistance, residual stresses, and wear resistance. Progress in compressor valve steels Over the past decades, Alleima, a manufacturer of high-value-added products in advanced stainless steels and special alloys, has pioneered advancements in compressor valve steels to meet the latest energy efficiency standards in HVACR (heating, ventilation, air conditioning, and refrigeration) applications. Freeflex® Versa represents substantial progress in compressor valve steel technology. Freeflex® Versa represents substantial progress in compressor valve steel technology Building upon the success of its predecessors Hiflex™ and Freeflex® Core this martensitic stainless steel is engineered, with a focus on catering to the unique requirements of reciprocating and linear technologies. Notable features of Freeflex® Versa include exceptional fatigue resistance, outstanding wear resistance, and the ability to contribute to noise reduction and downsizing. Development of the new compressor valve steel At the International Refrigeration and Air Conditioning Conference at Purdue University, Alleima, will present the exploration of the development of the new compressor valve steel variant Freeflex® Versa, as well as showcasing its dynamic valve steel portfolio, tailored to meet specific technological demands. The company's commitment to developing lighter, stronger, and more durable materials underscores its dedication to fostering energy-efficient and sustainable applications. "Even a small piece of steel can have a great impact. Our premium compressor valve steel provides increased design freedom, leading to more energy-efficient appliances and sustainable products," says Anders Hoel, Ph.D. in Material Science and Senior Research Engineer, at Alleima. New possibilities for enhancing performance The innovative Freeflex® Versa opens up new possibilities for enhancing performance and efficiency Alleima's compressor valve steel is ideally suited for a variety of applications, including air conditioning equipment, heat pumps, refrigerators, freezers, and clothes dryers. The innovative Freeflex® Versa, in particular, opens up new possibilities for enhancing performance and efficiency in these essential household and commercial appliances. The global demand for cooling systems is rising due to population growth, urbanization, higher living standards, and climate change. The International Energy Agency reports that air conditioners and electric fans account for about 20% of electricity used in buildings worldwide, or 10% of all global electricity consumption. Therefore, using more energy-efficient cooling systems is crucial. Research by Alleima over a 10-year period to 2022 showed that Alleima Hiflex™ improved air conditioner energy efficiency by an estimated 18%. Alleima Versa is the next generation of this product and advances energy efficiency further.

Quality Heating, Cooling, Plumbing & Electric, a renowned HVAC, plumbing, and electric service company located in Glenpool, Oklahoma, has acquired Frost Air Services and will retain the company’s owner to add to its pool of expert home comfort service technicians. Cody Frost started his Tulsa-area home service business in 2018 after serving as a lead technician for other heating and air conditioning companies in the area since receiving his associate’s degree in HVAC technology from the Oklahoma State University Institute of Technology in 2014. Addition to the Quality lineup Quality Heating, Cooling, Plumbing & Electric purchased Frost Air Service earlier this spring “Acquiring Frost Air Services strengthens our position in the HVAC industry and expands our market share in the Tulsa area,” said Quality Heating, Cooling, Plumbing & Electric Vice President and Co-Owner - Cassie Pound, adding “It’s also an honor for us to have Cody on board. He’ll continue to work as an HVAC field service manager for Quality, providing homeowners with the five-star service they’ve come to expect from our team.” Quality Heating, Cooling, Plumbing & Electric purchased Frost Air Service earlier this spring, just in time for the busy summer season, and Quality President and Co-Owner - Oscar Pound said Frost’s expertise will be a valuable addition to the Quality lineup. Frost Air Services “Cody’s experience and training have made him an excellent heating and air conditioning service tech in this community for many years, and we’re happy to have him join our team,” said Oscar Pound, adding “He built Frost Air Services into a top-notch home service company by making his customers his top priority. Quality will continue to provide impeccable services to his customers and ours.” Cassie Pound said Frost’s support of the community through local sponsorships mirrors Quality’s commitment to giving back to the residents of northeast Oklahoma, making Frost a great fit with the company. Frost Air Services served the greater metro Tulsa area and provided air duct and dryer vent cleaning in addition to its HVAC services.

Expert Commentary

How can UK businesses effectively tackle the challenge of cooling commercial and industrial buildings? Cooling commercial and industrial buildings can be a challenge for UK businesses. In recent years, the spiraling energy costs have put pressure on businesses with regard to finding new and innovative ways to achieve the same result with less capital outlay and less maintenance. New system installs have sometimes been put on hold and maintenance schedules squeezed, leaving many businesses with the challenge of managing aging HVAC assets and deciding when and where to invest. Systems without regular maintenance can experience unpredictable downtime and parts availability is not always guaranteed. Evaporative Cooling Evaporative cooling is an alternative cooling method that not only offers higher energy efficiency Business owners will always wonder how they can improve the cost-effectiveness, ease of maintenance, and sustainability of systems their business needs. When it comes to cooling business premises, there’s a solution that not enough people know: Evaporative Cooling. Evaporative cooling is an alternative cooling method that not only offers higher energy efficiency than alternative HVAC solutions but also has cheaper running costs. Since then, it has been our mission to develop and use this technology to tackle the cooling challenges in industrial processes. Cooling Challenges in Industrial Processes With regard to cooling, many industrial processes have a high heat gain, whereby the process itself generates heat which must be managed. There are numerous sectors where this is occurring, two prime examples from our customer experience are industrial-scale bakeries and plastic molding facilities. The production line may be operational 24 hours a day, seven days a week In an industrial-scale bakery using modern production methods, the production line may be operational 24 hours a day, seven days a week. The constant production of heat and steam from large ovens working to high temperatures must be managed carefully, especially given the health and safety requirements for food production areas. Heat gain from the industrial processes Plastic molding facilities manufacture a variety of end products from everyday items such as plastic bottles for household goods to more specialist storage and packaging products. In a plastic molding facility heat is used to mold the liquid plastic but chemical particles may also need extraction to maintain a safe working environment. Production in any of these facilities may be adversely affected by the heat gain in the process itself. Unplanned and unmanaged heat in any manufacturing facility has the potential to stop production resulting in a cascade of business interruption, lost revenues, damaged stock, and missed productivity targets. All potentially severe impacts for any business to consider. Plastic molding facilities manufacture a variety of end products. In addition to heat gain from the industrial processes, we should also note that UK air temperatures are rising, the top 10 warmest years for the UK since records began in 1884 have all occurred since 2002. As the UK continues to experience temperature rises and more seasonal fluctuations we need to look to those more experienced with warmer climates to optimize and improve our own approach to cooling these spaces. So, let’s consider the choices to cool large commercial and industrial spaces. Conventional air conditioning (AC) systems Cotton mills and textile plants were among the early adopters of the technological advancement Most of us will be familiar with conventional air conditioning (AC) systems but let’s review how they work: The first “modern” air conditioning unit was built by the American inventor Willis Carrier in 1902 and was used to control the temperature in the Sackett-Wilhelms Lithographing & Publishing Company in Brooklyn, New York. This innovation helped to control the paper dimension and ink alignment. Cotton mills and textile plants were among the early adopters with the technological advancement soon spreading across the world. Today a conventional AC unit removes heat and moisture from the air. It uses a chemical refrigerant to cool the air which is then re-circulated in the building. The same air is then filtered as it returns to the unit. Key Facts of Conventional Air Conditioning Temperature can be controlled. Air is mostly recirculated within the space or building. The resultant energy performance of the system can be negatively impacted by high external temperatures, i.e., the hotter the external temperature the greater the amount of energy needed to run the unit and maintain the desired temperature. Complete systems are expensive to install and maintain due to the more complex requirements associated with the refrigerants used within the units. The cost to run large systems is expensive resulting in high and unpredictable energy bills. Chemical refrigerants are used ultimately negatively contributing to climate change. Conventional air conditioning cannot be said to be a bad choice however, in our experience, it is more suited to smaller spaces with a defined use. Office spaces would be a good example of where air conditioning systems can still be a good solution albeit without the benefit of reduced running costs. A fantastic sustainable alternative to conventional air conditioning is an evaporative cooling system. Historically championed in warmer climate countries, the technology delivers several benefits over and above conventional and familiar air conditioning. Evaporative Cooling Solutions Fresh, filtered air enters the system and is pulled through a cooling pad Reflecting on global history, examples of evaporative cooling can be seen as far back as 1350AD. One case describes how in Cairo, Egypt, a building was purposely situated up-wind, to catch the air and let it flow down the building and across a fountain which increased the relative humidity and lowered the temperature of the surrounding air. A fascinating early adoption of the evaporative cooling effect. Evaporative cooling systems as the name suggests use evaporation to cool the air; surprisingly no chemical refrigerants are involved in this process. Fresh, filtered air enters the system and is pulled through a cooling pad where the heat is absorbed. The resultant cooled air is distributed throughout the space via ducts. Key Facts of Evaporative Cooling Temperature and humidity can be accurately controlled. Indoor Air Quality (IAQ) is improved because of the introduction of 100% fresh outside air this in turn improves employee comfort, health, and well-being and supports good productivity. Cooling performance is improved with increasing external temperatures–efficiency rises along with the temperature. Initial capital outlay costs are relatively low, in comparison to a like-for-like conventional air conditioning system. Running costs are low, lowering energy bills and energy dependence. Based on the evaporation principle and using only water to cool, combined with the lack of chemical refrigerant make evaporative cooling a responsible, energy-efficient, and sustainable choice for cooling your industrial or commercial workplace. Lowering Carbon Footprint with Evaporative Cooling The carbon footprint is a method of determining environmental impact Lower your business carbon footprint with an evaporative cooling system. When measuring a carbon footprint, it’s the amount of carbon dioxide directly or indirectly produced. The carbon footprint is a method of determining environmental impact. If an industry appliance uses a low level of electricity, it minimizes the environmental impact. Evaporative cooling systems can contribute to lowering the carbon footprint of your factory and warehouse in the following ways: Evaporative cooling products can use up to 82% less energy compared with conventional air conditioning. This is a huge saving both initially and across a lifespan of more than 15 years. Evaporative coolers also consume up to 30% less water than conventional AC systems despite relying on water to provide evaporation for the cooling effect! Addressing Industrial Hotspots In addition, industrial manufacturing workplaces often have hot spots that are uncomfortable to work in and those spaces are not just hotter than the rest of the building, but hotter than external ambient conditions. Evaporative cooling may be used to “spot cool” these hot spots and therefore reduce the need for the multiple units that would be needed to cool the entire space. Evaporative cooling is a proven technology perfect for all kinds of HVAC applications across multiple industries, this includes manufacturing plants and commercial warehouses. When cooling these large areas, evaporative cooling is repeatedly more cost-effective than traditional air conditioning. The primary benefit being the initial capital outlay to design and install the system is lower than conventional air conditioning. Secondly, the day-to-day running costs are again less owing to the reduced energy demand by the sophisticated technology used in these coolers. Unusually, these cost savings are also underpinned by the eco-friendly credentials of the technology, potentially contributing to reducing the carbon footprint of your business. This can be further enhanced by installing supportive clean energy technology such as solar power.

From temperate climates that reach mid-90 F in June and mild winters allowing people to be outdoors without jackets to the “May flowers” that bloom in early March, it’s evident that society is experiencing World Refrigeration Day’s 2024 theme: “Temperature matters.” In addition to driving climate change, global warming is driving changes in how people live and how industries adapt and innovate to support new dynamics. This is especially true for the HVACR Industry. Over the past several years, contractors have been busy installing and servicing cooling systems in climate zones that historically haven’t needed them. There’s a major focus on achieving more energy efficiency and lower water consumption in cooling the world’s escalating number of data centers. Impact on HVACR Industry There’s also increased demand to conserve water in cooling towers and/or adiabatic condensers and for elevated indoor environmental quality (IEQ) to improve health and productivity. A few examples show how rising global temperatures are impacting the HVACR industry These few examples demonstrate how rising global temperatures are impacting the HVACR industry. Sharing a huge part of the spotlight of industry solutions are refrigerants, which now need to work harder than ever to keep people comfortable and foods, beverages, and pharmaceuticals at proper temperatures. And they must do so without contributing to global warming and other environmental concerns. Refrigerant priority #1: lower GWP Assessing refrigerants for their ability to address climate change concerns starts with their global warming potential (GWP). That’s why attention has turned to A2Ls, which offer significantly lower GWP than legacy refrigerants. The three “big players” in the A2L arena—R-454A, R-454B, and R-454C—are now being selected for new-generation equipment solutions in various HVACR applications. A look at GWP reduction in a sampling of these applications tells the story: R-454A and R-454C can provide a 94% to 96% reduction in GWP as an alternative for R-404A, while offering similar performance Applications that historically would use a new R-410A unit can transition to R-454B, resulting in a 77% reduction in GWP. The industry is also choosing HFO-1234yf, an A2L currently used in air conditioners in 95 million vehicles on U.S. roads. HFO-1234yf has an AR4 GWP of 4 and is also used as a blend component in Chemours A1 and A2L products. Although A2Ls are for new equipment only, lower-GWP A1 refrigerant solutions can help in retrofits. For most applications using a higher-GWP HFC in an existing system, there’s likely a lower-GWP HFC/HFO blend for retrofit applications Other refrigerant priorities Of course, the value of a refrigerant is based on more than just low GWP Of course, the value of a refrigerant is based on more than just low GWP. The true innovation in refrigerant development lies in striking the optimal balance between environmental impact and performance for a diversity of applications. For example, after developing what are now considered three major players in the future of refrigerants—Chemours Opteon™ XL40 (R-454A), Opteon™ XL41 (R-454B), and Opteon™ XL20 (R-454C)—our chemists remain in the labs and work with pioneering industry partners to lower GWP even more, without compromising other properties. It’s important to consider how well a refrigerant addresses several key factors: Low GWP and zero ozone depletion potential (ODP) Reduced energy consumption Circularity—the ability to be recovered, recycled, and reclaimed Lower operating costs over the lifetime of equipment Safety—for everyone from technicians to end users Overall performance—measured by capacity, reliability, and efficiency Can be serviced by a large existing workforce of trained technicians Responsible manufacturing focused on reducing carbon emissions Availability and supply chain strength A2L refrigerants have been designed with these factors in mind, raising the bar in terms of performance and support for environmental priorities. Addressing climate zone challenges In addition to solutions designed for today’s many residential, commercial, and industrial cooling and refrigeration applications, the industry needs a full toolbox of systems, components, and refrigerants to meet—in a highly efficient manner—the challenges of cooling and heating in various climate zones. These range from Zone 1, which is very hot, humid, and dry, to the subarctic Zone 8 ASHRAE divides the U.S. into eight major climate zones. These range from Zone 1, which is very hot, humid, and dry, to the subarctic Zone 8. In between these two extremes, we find various levels of heat/cold, humidity, and dryness. These climate zones provide system engineers with guidance for choosing the best designs—including refrigerant selection—so that each zone can be equipped with the appropriate system, optimized for year-round capacity, efficiency, reliability, and more. New-generation heat pumps For example, the high heat and humidity of a tropical climate put heavy demand on cooling equipment—from air conditioners to refrigeration systems. These cooling systems are likely to run most of the year, so choosing a highly energy-efficient option is paramount. By contrast, we have zones with overall colder ambient temperatures. Heat pumps must be properly sized to ensure occupant comfort. Cooling systems in these climates have limited use during the year, but they must perform reliably when needed. In climates where heating buildings take priority over cooling them, we’re finding a significant transition from traditional AC-only units to new-generation heat pumps. Heat pumps must be properly sized to ensure occupant comfort and keep the heat pump from “struggling” to control humidity when operated in AC mode. Choosing refrigerant solutions There is no question the world’s temperature is on the rise. According to the National Oceanic and Atmospheric Administration, since 1982, the rate of the Earth’s warming has risen approximately 0.36 F (0.20°C) per decade—more than three times the average rate of all previous decades measured. The 10 warmest years on record all occurred in the past decade. And 2023 was the warmest year on record for North America, South America, and Africa, as well as the second warmest for Europe. As climate change continues to warm up winters and heat up summers, refrigerants will play an increasingly important role in “cooling down” people and products and helping to reduce the impact that industry and society have on “heating up” the planet. Everyone can do their part by understanding that temperature matters, then choosing refrigerant solutions that have lower GWP, support other environmental needs, and offer the right combination of performance attributes for a given climate zone.

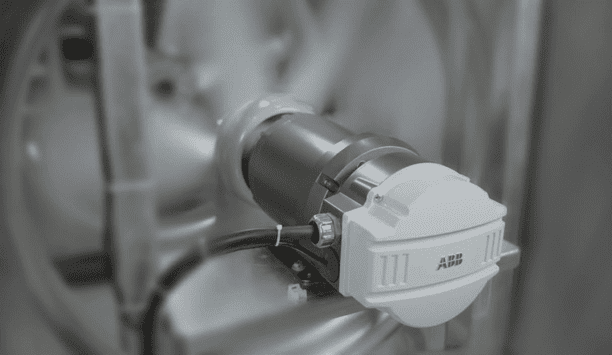

Advanced heating, ventilation, air-conditioning, and refrigeration (HVACR) systems have always been essential to healthcare. However, the need for clean, fresh air at the right temperature and humidity within clinical settings has never been made clearer during the COVID-19 pandemic. It illustrated the importance of effective HVACR systems in healthcare due to their ability to improve air quality, patient outcomes, and infection control measures. The need for change Many current HVACR systems are outdated. Their reliance on direct on-line motor connection and mechanical methods to regulate fans, pumps, and compressors leads to inefficient energy use, generating higher costs. However, switching from manual methods to variable speed drives (VSDs) to regulate motor speeds can save as much as 25% in HVACR energy use, reducing operational costs in the process, and improving air quality control. The adoption of advanced ultra-low harmonic VSDs also improves power network reliability and efficiency. variable speed drives (VSDs) There’s the added benefit that the facility can save on the capital costs of the equipment and space VSDs also play a pivotal role in expanding the design capabilities of HVACR. One key advantage is their ability to over-speed fans within the system to cover higher loads than the system was designed for. This flexibility allows them to operate in extreme conditions and still meet the needs of the facility, without installing significantly oversized systems to cover these rare peak loads. There’s the added benefit that the facility can save on the capital costs of the equipment and space where it is installed. The challenge of harmonic distortion While newer healthcare facilities may already be equipped with HVACR systems controlled by VSDs, older facilities may require significant upgrades. Some VSDs can introduce unwanted electrical disturbances to the facility network, called harmonics, which affect the performance of electrical equipment and lead to higher energy losses. Harmonics increase line current, meaning that when fitting VSDs, power cables, and other components might need to be re-sized to be able to accommodate it. Filtering and control mechanisms Advanced ultra-low harmonic VSDs are designed to mitigate the impact of harmonics on electrical systems To address this issue, advanced ultra-low harmonic VSDs are designed to mitigate the impact of harmonics on electrical systems. Ultra-low harmonic VSDs incorporate sophisticated filtering and control mechanisms to reduce harmonic distortion, ensuring the reliability and efficiency of electrical infrastructure within healthcare facilities, including medical equipment used to treat patients. They also mitigate the need for a larger refit and higher maintenance costs, while ensuring compliance with regulatory standards governing harmonics and electrical quality. Understanding the crucial role of air quality Maintaining high air quality standards within hospitals is essential to minimize the risk of healthcare-associated infections (HAIs) and ensure the safety of both patients and medical staff. Poor air quality can lead to higher concentrations of bacteria, viruses, and fungi in the air, significantly increasing the risk of HAIs. These infections can lead to prolonged hospital stays, compromising patient safety, and further increasing healthcare costs for patients and providers. This is exactly what the COVID-19 pandemic highlighted. Regulatory standards and guidelines Only advanced ventilation systems controlled by VSDs can fully deliver what’s required Given these significant risks associated with poor air quality, healthcare facilities are subject to stringent regulatory standards and guidelines governing indoor air quality. Compliance with these standards is essential, and only advanced ventilation systems controlled by VSDs can fully deliver what’s required. Breathing easier In conclusion, advanced HVACR systems controlled by ultra-low harmonic VSDs are essential for healthcare facilities seeking to improve air quality and provide a healthier environment for patients and staff. They also enhance energy efficiency and optimize associated costs, while ensuring compliance with regulatory standards. Adopting these advanced drives offers improved medical equipment reliability, as they take care of power quality and minimize electrical disturbances in the facility's power network. Ultimately that leads to better patient outcomes and hospital operational efficiency.

Editor's Note

SNAP Rule 26 marks an important milestone in the transition from commercial refrigeration to new refrigerants. The rule lists refrigerant substitutes that provide a spectrum of technological solutions to meet required performance, global warming potential (GWP), safety, and environmental standards. SNAP stands for Significant New Alternatives Policy, a program by the U.S. EPA (Environmental Protection Agency) under the Clean Air Act. In general, the program aims to evaluate and regulate substitutes for ozone-depleting substances, considering their overall risks to both human health and the environment. Impact of SNAP Rule 26 Final SNAP Rule 26, Protection of Stratospheric Ozone, lists acceptable substitutes in commercial and industrial refrigeration. SNAP Rule 26 will be effective July 15, 2024. The incorporation by reference of certain material listed in the rule is approved by the Director of the Federal Register as of July 15, 2024. The incorporation by reference of certain material listed in the rule is approved by the Director of the Federal Register “To date, the SNAP program has provided a very effective framework for evaluation and approval in support of innovation and the transition to new technology,” says Andrew Pansulla, Technical Service Engineer, The Chemours Company, a global chemistry company that provides a range of refrigerant products. We asked Pansulla to elaborate further on the impact of SNAP Rule 26 and what lies ahead. Q: How will the Rule’s finalization impact various commercial refrigeration sectors? Pansulla: The rule’s finalization will impact commercial refrigeration in several ways. Areas, where impact will likely be seen, include providing more acceptable refrigerant options, adherence to updated standards, new equipment design standards, and the exemption of propane from the venting prohibition for refrigerated food processing and dispensing equipment. These impacts could trigger changes in operational, manufacturing, and environmental compliance strategies in the commercial refrigeration sectors. SNAP Rule 26 will enable the adoption of the listed substitutes, including Chemours Opteon™ refrigerants, with global warming potential (GWP) lower than existing refrigerants. This rule does not require any changes to existing equipment and will impact only new equipment that uses the specific substances referenced in the SNAP rule. Q: What is the outlook for additional requirements for safe handling and use of alternative refrigerants? What specific safety standards are expected or appropriate? Pansulla: As part of the comparative risk framework used by the EPA to assess new alternatives, the EPA considers and implements use conditions that will ensure the safe use of products. These use conditions rely upon existing safety standards (e.g., UL and ASHRAE) which are available at the time the rule is finalized. In the case of SNAP Rule 26, many of the use conditions require adherence to UL 60335-2-89 and ASHRAE-15-2022. These standards are reviewed and updated periodically to maintain relevance with the products subject to the standards. Q: What are any limitations of the use of A2L refrigerants under SNAP Rule 26? Pansulla: There are two main categories of limitations under SNAP Rule 26. The first, as mentioned above, is the adherence to specific safety standards that apply to refrigerants that are designated as mildly flammable (A2L). The second is based on the GWP of the refrigerant. In the case of the A2L refrigerants subject to SNAP Rule 26, the EPA imposed conditions on the type of equipment and specific circumstances in which the substitute may be used. For example, the EPA is permitting the use of R-454A in supermarket systems, but only on the high side of a cascade system, or when the refrigerant charge capacity is less than 200 pounds. Q: Which new-generation A2L refrigerants are fit for which commercial refrigeration applications? Pansulla: Under SNAP Rule 26, the EPA deems R-1234yf, R-1234ze(E), R-454C, R-455A, R-457A, and R-516A as acceptable subject-to-use conditions for various commercial refrigeration applications. This selection is primarily driven by these refrigerants having GWPs under 150. However, certain applications necessitate refrigerants with higher GWPs due to unique performance characteristics. For example, R-454B and R-32 were listed for industrial process refrigeration with exiting fluid temperatures below minus 30 degree Celsius because these two specific refrigerants have lower boiling points than the other six less-than-150-GWP alternatives. However, it is critically important to consider the additional use conditions when designing equipment with refrigerants that have a GWP greater than 150. Q: So various equipment needs different refrigerants? Pansulla: The EPA purposefully lists several different refrigerants in each application to allow for equipment manufacturers to consider a variety of different factors that go into refrigerant selection, such as energy efficiency, capacity, normal boiling point, temperature glide, cost, safety, and use conditions. There is no one-size-fits-all solution for the entire commercial refrigeration industry. Q: How can commercial refrigeration businesses achieve a smooth transition to A2Ls? Pansulla: Keys to a smooth transition to A2Ls include understanding what refrigerants the EPA has approved as acceptable substitutes under the SNAP program, the sector-based GWP limits imposed by the Technology Transitions Program under the American Innovation and Manufacturing (AIM) Act, and which refrigerants provide the best combination of technical performance and environmental characteristics. Many resources are available to navigate the regulatory landscape and select the best low-GWP refrigerants to meet the needs of this industry. Working with companies like Chemours, who has nearly a century of refrigerant innovation and experience, is a great first step in the transition process. Q: What is the “staying power” of A2Ls — based on their chemistry, sustainability, and other attributes, combined with regulations such as SNAP Rule 26? Pansulla: The identification, selection, and development of new refrigerants that deliver required performance while meeting increasingly stringent environmental standards is a challenging process. With the identification of certain hydrofluoroolefin-based (HFO) refrigerants as an alternative to meet these criteria came a new safety classification. These HFO-based refrigerants are classified as A2Ls. While slightly more flammable than existing hydrofluorocarbon-base (HFC) refrigerants, HFOs are much less flammable than hydrocarbons, which are classified as A3 (two categories higher on the ASHRAE flammability spectrum). Moreover, such refrigerants offer an excellent alternative to substances with higher toxicity, such as R-717. The listing of A2L refrigerants in SNAP Rule 26 clearly indicates that such refrigerants can be used safely in commercial refrigeration as well as many other applications, which are subject to the SNAP Program, when adhering to the applicable safety standards.

Humidity can influence employee health and productivity in the workplace. Humidity, temperature, and ventilation all work in concert to create a healthy indoor environment that supports overall occupant well-being. “Dry indoor air can cause discomfort in the form of dry skin, eyes, and throat for staff and visitors,” says Jennifer Montville, Director of Marketing at DriSteem, a manufacturer of humidification systems. Air-related health issues “There are real costs associated with health-related issues caused by dry air, including a higher occurrence of infections and increased rates of staff absenteeism?” Maintaining a comfortable work environment, including the correct humidity levels, prevents respiratory issues and reduces the spread of illnesses, ensuring a healthy working environment and boosting productivity and efficiency, says Montville. humidity levels Humidified spaces help keep facility costs down by improving thermal comfort at lower temperatures Maintaining humidity levels between 40% and 60% RH is ideal for mitigating virus transmission, she comments. Humidified spaces feel warmer and are more comfortable for employees, which in turn increases their productivity with improved concentration and less fatigue. It also helps keep facility costs down by improving thermal comfort at lower temperatures. dehumidifiers Employing dehumidifiers to keep humidity levels from rising above that 60% RH threshold is also important. Removing excess moisture from the air reduces distraction from unpleasant smells or health issues caused by mold, mildew, or fungi that thrive in moist environments. All the ways that proper humidity levels affect employee health and productivity in the workplace also contribute to increased customer satisfaction in office and retail spaces, says Montville. preventing product issues “We all prefer to spend time in places where we feel physically comfortable,” she says. “Customers in offices and retail spaces are no different. When physical comfort is not an issue, we are likely to spend more time and engage more deeply.” Well-managed humidity levels also help to prevent product issues such as shrinkage, warping, or degradation due to moisture fluctuations. Food quality is particularly impacted by humidity levels. In a retail store, this can translate to spending more time shopping in a store and a more positive opinion of the products being considered. recommended indoor relative humidity level Keeping relative humidity levels within the range ensures the health and safety of building occupants The recommended indoor relative humidity level ranges from 30% to 60% RH, according to guidelines published by the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE). Keeping relative humidity levels within this range ensures the health and safety of building occupants without promoting mold growth or other indoor air quality issues. air quality goals With that said, the type of indoor space, air quality goals, and how the space is used will determine the best relative humidity levels for each facility, according to Montville. Machinery and sensitive electronic equipment are vulnerable to low or fluctuating moisture levels. Static electricity buildup and electrical malfunctions are among the potential consequences of inadequate humidity control. precise humidity control Many industrial processes depend on the consistent quality of materials, and fluctuations in relative humidity (RH) can result in less-than-ideal inputs which in turn impact the quality of final products. From preventing mold growth, spoilage, and texture deterioration in food processing to safeguarding medication stability, efficacy, and safety of pharmaceuticals, precise humidity control is critical to achieving intended results. Optimal RH levels Adequate humidity also supports the body's natural defense mechanisms, enhancing the effectiveness Maintaining appropriate humidity levels is essential for infection control. Optimal RH levels can inhibit the growth and transmission of airborne pathogens, such as viruses, bacteria, and fungi. Adequate humidity also supports the body's natural defense mechanisms, enhancing the effectiveness of respiratory tract mucous membranes in trapping and neutralizing pathogens. Conversely, dry indoor air impairs these defenses, increasing susceptibility to respiratory infections. humidity control systems Investing in commercial humidity control systems, such as those offered by DriSteem, can effectively regulate RH levels within facilities. “These systems provide flexibility and precision in catering to specific humidity needs across different areas within the facility,” says Montville. Whether integrating humidity control solutions in existing structures or implementing them in new buildings, factors such as the type of indoor space, energy source, required maintenance, and capacity determine the best technology for each building, she says.

It takes a proliferation of data centers to serve the growing computing needs of the Internet, and all those servers churning away create plenty of heat. Might some of that heat be harnessed and used for residential or commercial heating? The emergence of district heating systems, which provide thermal energy to multiple buildings from a single source, demonstrates the approach has broad possibilities. Air-cooled chillers and air-handling units used to cool data centers are like the technologies that cool residences and businesses. They just operate on a larger scale and require a higher degree of resilience and redundancy to ensure data center servers operate without interruption. District heating system The law of physics dictates that the energy you put into a data server will come out as heat, and heat is a byproduct of data center cooling systems. Rather than exhaust that heat into the outside environment, how can it be captured and channeled into a district heating system to heat water and/or to provide warmth to homes and businesses in the same neighborhood as the data center? Law of physics dictates that the energy you put into a data server will come out as heat Mitsubishi Electric designs engineered solutions that both cool data centers and generate heat output that can be captured for district heating applications. “We want to capture the heat and repurpose it for someone else to use,” says Simon Prichard, Product Strategy Manager for Engineered Solutions for Mitsubishi Electric. Reusing wasted heat from data centers can help to decarbonize heating. United Kingdom's Energy Act 2023 An additional heat pump can be used to increase the “low-grade heat” generated by a data center to the temperature needed for district heating. Alternatively, district heating systems might be upgraded to accommodate the lower-temperature heat from data centers. Additional heat pump can be used to increase the “low-grade heat” generated by a data center. The United Kingdom and other governments globally are promoting the creation of district heating networks. Legislation such as the United Kingdom's Energy Act 2023 identifies areas within England where certain new and existing buildings will be required to connect into district heating networks. Legislation is pushing developers toward district heating and away from the use of fossil fuels. District heating applications Water cooling is a developing technology for data centers, which mostly use air-cooling systems In November 2023, the UK government awarded £36 million to a district heating system in West London that will share data center waste heat with up to 10,000 new homes. Hot air from a data center can provide some of the energy needed for a district heating system, and water-cooling systems can provide even more. Water cooling is a developing technology for data centers, which mostly use air cooling systems. Cooperation is needed to realize the scenario of capturing the heat from data centers for district heating applications. Government legislation can drive requirements to embrace the approach, but the multiple involved parties, including data center operators and the architects and engineers creating nearby communities, must also cooperate. Greater ESG goals Energy must be reused in the geographic area immediately surrounding the data center for the scenario to be financially viable. In an industrial estate, for example, the excess heat could be used for nearby farming; the reuse is not restricted to domestic or residential applications. The various parties tend to be “siloed,” so a concerted effort of “joined-up thinking” is needed to bring all the parties to the table to enable such a system. Construction of new data centers is accelerating, and the centers are getting larger. Construction of new data centers is accelerating, and the centers are getting larger. Currently, 4 or 5% of total electricity output is used by data centers, and ways to reuse that energy are a growing priority for ethical companies in the data center market. Large companies that use data centers are drawn to the district heating scenario to achieve greater ESG (Environmental, Social, and Governance) goals. Moving forward, it behooves everyone to think of data centers as not just generating data but as energy centers generating sustainable energy. Mitsubishi Electric’s products MEWALL mixes high version with energy efficiency, space optimization, and cost-effectiveness “We live in a connected world, and we need data centers,” says Prichard. “The world won’t work without them, but many people don’t know what a data center is and how much we rely on them. Society doesn’t realize how embedded they are.” Among Mitsubishi Electric’s products for the data center market is the MEWALL air handling unit, a “wall” of fans with built-in controls, valves, and filters that are mounted alongside a suite of data servers. MEWALL combines high performance with energy efficiency, space optimization, and cost-effectiveness. Water circulates inside the fans, using cold water produced by a chiller. View of the MEWALL system Smaller data center needs can be addressed using technology such as Mitsubishi Electric’s indoor s-MEXT high-precision air conditioner connected to a Mr. Slim R32 Power Inverter outdoor unit. The indoor unit is customized to the client’s requirements for use in a data center. At the Data Center World trade show in London in March, Mitsubishi Electric used virtual reality (VR) to provide attendees with a simulated view of the MEWALL system. Given the dimensions of 4 by 2.3 meters, transporting the system to the show presented prohibitive cost and logistical challenges.

Case studies

To offset the cost of tenants’ monthly electric bills and provide prospective residents with high-quality HVAC upgrades that prioritize comfort and performance, Samuels Associates, owner of the Fenway Triangle luxury apartments, sought a new, building-wide heating solution that was not only cost-effective but also added a modern touch to the building’s extravagance. QMark® MUH-Pro+ and CU900 electric heaters with SmartSeries® Plus (SSP) digital BACnet thermostats from Goodyear HVAC Sales proved to be the ideal solution. Heat in a contemporary design “From their energy efficiency, quiet operation and low maintenance to the fact that they can be controlled individually for personalized comfort, electric heaters offer several benefits in apartment buildings,” explained Andrew Martin, Manager of Product Management with Marley Engineered Products® (MEP). “Delivering supplemental comfort heat in a contemporary design, these heaters are ideal for a variety of spaces including school hallways, church vestibules, transportation terminals, stairwells, entrances, lobbies, mechanical rooms and more.” Installing Heaters while Maintaining esthetics Buildings boast modern frills and discreet and esthetically good HVAC plans that act quietly Steps away from the iconic Fenway Park, the Fenway Triangle is an 891,000-square-foot complex comprising more than 570 luxury apartment units, as well as an eclectic mix of national and local retailers, restaurants, shops and green spaces. Since opening in 2006, the building needed to address issues with its HVAC systems and controls, which were leading to high monthly electric bills. The culprit? More than 50 outdated competitor electric terminal heaters, which offered only on/off controls and needed to be operated manually. If the maintenance team forgot to shut off the heaters, "The Fenway" would incur the cost of each heater running at full capacity at a rate of about 27 cents per kilowatt-hour. Another challenge facing Fenway Triangle: The emergence of new luxury apartment complexes. These buildings boast modern amenities and discreet and esthetically pleasing HVAC systems that operate quietly. They pose significant competition for “The Fenway”, as tenants increasingly prioritize indoor air quality (IAQ) and HVAC performance when selecting their luxury residences. To remain competitive in the luxury apartment market, investing in HVAC upgrades to replace outdated equipment is imperative. QMark MUH-Pro+ and CU900 electric heaters Heaters were installed in elevator banks, stairwells, worker lounges, hallways, and facility To combat the rising cost of heating each unit within the building, MEP’s local Sales Representative, Goodyear HVAC Sales, worked with HVAC distributor Equipment Direct Sales, Inc. (EDSI) to provide the client with energy-efficient QMark MUH-Pro+ and CU900 electric heaters from Marley Engineered Products. Designed to maintain occupant comfort and a comfortable environment, the heaters were installed in various elevator banks, stairwells, employee lounges, hallways and inside the building’s recently upgraded building management system (BMS) room. “Equipped with SSP digital thermostats that provide connections to BACnet MS/TP BMS for easy control and monitoring, the MUH-Pro+ and CU900 units only run when directed by the internal schedule of the BMS,” said Matthew Goodrich, President of Goodyear HVAC Sales. “Use of the BMS saves time and reduces personnel costs by eliminating the need to travel to the heater site. And, if a BMS is not available, the maintenance team can simply use the built in seven-day programmable scheduling feature.” New electric heating units Cost-Effective Heat for Unmatched Comfort and Lower Monthly Bills In tandem with EDSI, Goodrich and his team installed several brand-new electric heating units in The Fenway’s BMS room to provide cost-effective warmth without taking up floor space or creating a tripping hazard. “Innovation and collaboration converged as we tailored a custom heating solution, seamlessly blending functionality and aesthetics,” explained Goodrich. “In fabricating this solution for the client, our dedicated team and the coordination of skilled contractors transformed this building into a space that harmonizes comfort and elegance and exemplifies the blending of form and function.” Full control of the entire heating system The thermostats include features that allow the building’s maintenance team to monitor each heater The success of the project resulted in an extremely satisfied customer. Already, the SSP thermostats have provided cost savings by turning on the heaters only when needed, resulting in less electricity usage throughout The Fenway. Additionally, the thermostats include features that allow the building’s maintenance team to monitor each heater individually from within the BMS room, granting them full control of the entire heating system and eliminating the daily trips previously needed to turn each heater on and off. “We’re already seeing the savings associated with the upgraded controls,” said John Belmonte, Head of Trilogy Operations for the Fenway Triangle. “Being able to control over 40 heaters locally allows our team to focus on tenant needs without being bogged down by the time it takes to touch each individual unit. We’re eager to work further with the Goodyear team on other buildings in the neighborhood.” Innovative approach and exceptional achievements To acknowledge the innovative approach and exceptional achievements demonstrated by the Goodyear team in overcoming the challenges faced during this project, Marley Engineered Products awarded Goodrich the 2024 Jim Herring Memorial Silver Fox Award at its recent national sales meeting. “This award for excellence in solution design embodies the spirit of Herring, who left a lasting legacy of designing creative solutions for specialized applications, was always up for a challenge and most happy when solving a unique heating or ventilation problem,” said Sean Pesce, Director of Sales for Marley Engineered Products. “Matthew and his team at Goodyear perfectly captured Jim’s talent for finding creative solutions to the most complex issues and left a lasting impression on the client.”

Shadow Industrial (SI), one of the UK’s pioneering infrared heating specialists, has been chosen to refit the heating systems at the London Boroughs of Camden and Islington’s jointly-owned Hornsey Street Refuse & Recycling Center. The decision to use SI’s cutting-edge heaters was made on the recommendation of M&E contractor, Vitalenergi London, which was appointed to update the site’s HVAC. Operational Emissions By 2030 Replacing the building’s 300 m2 existing AmbiRad fan heater system, at just over £25,000, the project will see Shadow Industrial fit 35 of its zero-emission, high-performance heaters across the entire facility. This comes in at a far lower cost, often a 50-75% saving, and increased efficiency than many other alternative electric heating systems. The project will see Shadow Industrial fit 35 of its zero-emission, high-performance heaters Predicted to reduce energy consumption by 80%, this represents a landmark moment for shortwave infrared in industrial settings. Not only that, the replacement of existing heating systems with a low-cost, more sustainable alternative perfectly aligns with both Camden and Islington Council’s Climate Action Plans which seek to achieve Net Zero operational emissions by 2030. Shadow Industrial’s Technology As Graham Hughes from Islington Council says, “When Vitalenergi first introduced us to Shadow Industrial’s technology we were very impressed, particularly by its capabilities and relatively low operational costs." "It’s going to make a massive contribution to our efforts, alongside Camden Council to reduce emissions. We’ll also be able to approach our heating strategy in a far more diverse way, keeping costs down and passing those savings onto taxpayers.” The Heat Is On The technology works by emitting focused radiant heat through precisely-configured reflectors Not only will Shadow Industrial’s heating systems shrink the center’s carbon footprint, but they will also improve energy efficiency. This is predominantly due to the way shortwave infrared works, in contrast to traditional electric and gas-powered central heating. The technology works by emitting focused radiant heat through precisely-configured reflectors. Essentially it heats the person, not the air around them, significantly reducing the amount of heat lost to the atmosphere. This comes into its own in large-span, high-ceilinged structures that experience heavy traffic constantly entering in and out, pioneering to a consistent draft. Wall-mounted or ceiling-hung, directed downwards at individuals, the energy creates a comfortable and instant warmth reminiscent of the gentle heat of the sun. In Control Plug-and-play these light heaters are easy to install and operate, compared to formal systems Plug-and-play these lightweight heaters are easy to install and operate, compared to traditional systems. It’s helping to get a practical and scalable heating network up and running within an industrial facility quickly, with minimal disruption to day-to-day operations. Even better, unlike most gas and electric systems, these heaters can be turned on and off on demand as and when personnel are working in specific areas across the site. The instantaneousness of the heat emitted means it can deliver maximum effectiveness at the click of a switch, and extinguish at the same rate. This means no part of the build is heated unnecessarily. Shadow Industrial’s Heaters As Luke Chappell, Vitalenergi’s lead design engineer (mechanical) on the project says, “Shortwave infrared’s set to be a serious market disruptor in the industrial heating market. It’s a game-changer for local authority and public sector projects, which are both subject to strict sustainability briefs and budgetary constraints." "We cannot wait to see the positive impact Shadow Industrial’s heaters will have on those working within, and managing, the Hornsey Street Refuse & Recycling Center. The Shadow Industrial team has been amazing throughout the process and we looking forward to partnering again on future projects.” Installation of Shadow Industrial’s new system was completed at the start of Q2 2024.

Tucked into the rolling hills of northern Kentucky just 15 miles south of bustling Cincinnati, the city of Independence offers its 28,000 residents access to urban amenities in a picturesque, rural setting. The landscape is dotted with farmhouses, but one 200-year-old home on a sprawling 150-acre property has a unique story. Originally a log cabin in the 1700s, the house has been transformed over the centuries, with structural elements, updates, and modern comforts added along the way. The renovations, including a large expansion in the1920s and a handful of recent modernizations, have kept the home livable throughout the generations. historical integrity with comfort The current owner, Dr. C.J. “Jay” Hellmann, was 6 years old when he moved into the house. His fond memories of growing up on the farm are coupled with memories of sweating through the summer months. With its historic charm and cherished family memories from across the decades, the home means everything to him and his family, who value the farmhouse’s historical integrity but also require modern comfort. Efficient and effective cooling and heating Hellmann focused on making the house more comfortable by finding effective and efficient ways to heat and cool As Hellmann prepared the home for his daughter and son-in-law to move into, he focused on making the house more comfortable by finding effective and efficient ways to heat and cool the living areas. “The family had an oil furnace. They’re very expensive to run, not very efficient, and [produced] dirty air. The next generation moved in and wanted something a little more comfortable and cleaner,” said Josh Williams, Sales Manager, Corken Steel Products. Project highlights The farmhouse had both a rich history and antiquated infrastructure. It was steam-heated by a large, inefficient oil furnace in the basement and did not have ductwork or an air conditioner. Hellmann and his family felt the lack of air conditioning acutely during Kentucky’s humid summer months, which frequently see temperatures over 90°F. The family sought an HVAC solution that would fit their needs without compromising the farmhouse’s historic aesthetic. Inverter technology As the owner of Call Now Heating and Cooling, an Independence-based HVAC contracting business, Hellmann was familiar with LG but hadn’t considered the brand’s inverter technology until he met an LG sales representative at a local event. The two discussed the benefits of heat pump technology and how an LG system could suit the home’s needs. Shortly after, Hellmann scheduled a walkthrough of the house, which helped determine the best comfort solution to condition the home evenly and efficiently while preserving its charm. Quality and availability Hellmann and his team collaborated with Corken Steel and LG to design an energy-efficient solution “I have an HVAC business and I can pick any equipment I want,” he said. “I picked LG for a few reasons, including the quality of the equipment that we looked at, the availability, and that it matched, it looked good in the home. The support from LG was also a key part of my decision.” Hellmann and his team at Call Now Heating and Cooling collaborated with Corken Steel, a ductwork fabricator and HVAC wholesaler, and LG to design an energy-efficient solution that tackled the challenges of bringing modern HVAC products into a coveted older home. Challenges Older homes can pose significant heating and cooling challenges due to inadequate insulation, uneven heat distribution from existing systems, and a lack of ductwork. With traditional systems, this combination of obstacles can lead to expensive and invasive installations where large units take up valuable space. Hellmann sought a solution that would avoid these disruptions and involve fewer adjustments to the home’s footprint and architecture. He found that an all-electric inverter heat pump system from LG addressed all these challenges. Solution The team decided on a whole-home solution using two Multi F Max withLGRED° units to deliver customized comfort to every part of the house. One low-static ducted unit can heat and cool the first level, and six low-wall ductless console units can condition the second floor. After selecting the system, the team began installing it in harmony with the farmhouse’s environment, which required hiding the equipment wherever possible. Together, they determined how to work around steam pipes, where to run lines and drains, the layout of units, and where to place the equipment to maximize airflow. Given the farmhouse’s historic nature, this was not a simple installation; it required the team’s ingenuity and dedication to maintaining the integrity. Refrigerant and power/communication lines The first-floor units use minimal duct runs installed through the floors and into the basement The first-floor units use minimal duct runs installed through the floors and into the basement, where the old boiler system was located. Rather than installing multiple ducted systems for heating and cooling throughout the farmhouse, the team ran refrigerant and power/communication lines discretely through the attic for the low-wall console units in the upstairs rooms and sunroom and utilized an old, unused, laundry chute to run lines into the basement and outdoor units. Comprehensive solution “Our representative from LG made it exceptional to work together. He always answered when we had a question, and if he didn’t know the answer, he told us who to call to get what we needed,” said Brad Helton, HVAC Technician, Call Now Heating and Cooling. The strong relationship between Call Now Heating and Cooling, Corken Steel, and LG made it possible for Corken and Call Now to design a comprehensive solution to fit Hellmann’s needs, streamline installation, and create benefits they hadn’t originally anticipated. Result Ultimately, the team’s main priority was met, the new HVAC system complemented the home’s aesthetic and preserved its historic charm, efficiently heating and cooling. The LG low-wall units’ appearance blended nicely with the farmhouse’s style and their flexibility and small footprints meant they could be placed with consideration for the rooms’ designs. Aesthetics aside, the Hellmann farmhouse reaps many additional benefits from the LG system. The homeowners now enjoy consistent, customized comfort along with reduced noise, improved indoor air quality, and greater energy efficiency. All-electric heating All-electric heating means Hellmann no longer pays for oil to heat the home in Kentucky’s cold winters “The system has better air quality, it’s easier to and the units put out a very hot heat and very cool air compared to a normal heat system,” said Casey Whalen, Installation Manager, Call NowHeating and Cooling. All-electric heating means Hellmann no longer pays for oil to heat the home in Kentucky’s cold winters. This is a significant contributor to energy savings. Zoned comfort control With the old furnace, he’d spent nearly $1,500 every 30-40 days for oil. Now, with the all-electric LG system, he pays about a quarter of that, even in the coldest months. Zoned comfort control offered by the LG system also contributes to energy savings. Using thermostats, remote controls, and smartphone applications, the family can set each zone in their home to a different temperature or even turn units off altogether, depending on the room’s use and occupancy. All-electric LG inverter heat pump “Having a new LG system in this home is very exciting,” shared Hellmann.“We’re able to have cool air in a house that’s 200 years old and has never had cool air before. This was the first summer that you could sit in here and be comfortable, have fresh air, and comfortably use different rooms like the porch. It has made the house more livable, much more useful, and much more comfortable.” Breathing new life into a centuries-old home is a tough task. For the family, the fix has been renovations and modernizations over the years. And Hellman says none stands to benefit the family more or give them a greater return on their investment than the all-electric LG inverter heat pump system. LG HVAC Products Multi F Max with LGRED° Low Wall Console Low Static Ducted Distribution Box Y Branch Connector Wi-Fi Module with LG ThinQ Compatibility Standard III Wired Remote Controller